+91-8929850234

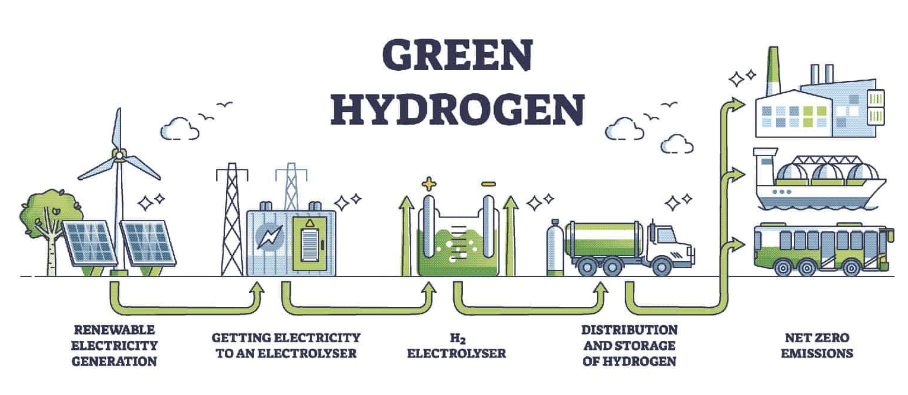

Green hydrogen has emerged as a critical player in the global shift towards sustainable and low-carbon energy solutions. Unlike conventional hydrogen production methods that often rely on fossil fuels, green hydrogen is produced using renewable energy sources, primarily through electrolysis.

Green hydrogen (GH2 or GH2) is hydrogen produced by the electrolysis of water, using renewable electricity. Production of green hydrogen causes significantly lower greenhouse gas emissions than production of grey hydrogen, which is derived from fossil fuels without carbon capture.

Green hydrogen’s principal purpose is to help limit global warming to 1.5C, reduce fossil fuel dependence by replacing grey hydrogen, and provide for an expanded set of end-uses in specific economic sectors, sub-sectors and activities. These end-uses may be technically difficult to decarbonize through other means such as electrification with renewable power. Its main applications are likely to be in heavy industry (e.g. high temperature processes alongside electricity, feedstock for production of green ammonia and organic chemicals, as an alternative to coal-derived coke for steelmaking), long-haul transport (e.g. shipping, aviation and to a lesser extent heavy goods vehicles), and long-term energy storage.

As of 2021, green hydrogen accounted for less than 0.04% of total hydrogen production. Its cost relative to hydrogen derived from fossil fuels is the main reason green hydrogen is in less demand. For example, hydrogen produced by electrolysis powered by solar power was about 25 times more expensive than that derived from hydrocarbons in 2018.

**1. Production Process:

Electrolysis:

Green hydrogen is predominantly produced through a process called electrolysis. This involves using electricity to split water (H2O) into hydrogen (H2) and oxygen (O2). The key differentiator in green hydrogen production is that the electricity used in the process is sourced from renewable energy, such as solar, wind, or hydropower. This ensures that the overall production cycle is environmentally sustainable.

Types of Electrolysis:

Proton Exchange Membrane (PEM) Electrolysis: PEM electrolysis employs a proton exchange membrane cell to facilitate the electrolysis process. These systems are known for their high efficiency and flexibility, making them suitable for various applications, including decentralized and small-scale installations.

Alkaline Electrolysis: This method uses an alkaline solution as the electrolyte. Alkaline electrolyzers are generally less expensive than PEM electrolyzers but may have slightly lower efficiency. They are often considered for larger, centralized installations.

Solid Oxide Electrolysis: Operating at high temperatures, solid oxide electrolysis is suitable for large-scale applications. These systems are characterized by high-temperature tolerance, making them potentially more efficient in certain industrial settings.

The foundation of green hydrogen production lies in the utilization of renewable energy sources. Solar, wind, and hydropower are the primary sources of electricity that power the electrolysis process. The choice of energy source depends on geographical location, availability, and economic considerations. By harnessing energy from these renewable sources, the entire value chain of green hydrogen production remains environmentally friendly, with minimal carbon emissions.

Green hydrogen is hailed for its significant environmental benefits. Unlike conventional hydrogen production methods, which often release carbon dioxide and other greenhouse gases, green hydrogen production is virtually emission-free. This aligns with global efforts to mitigate climate change and reduce the carbon footprint associated with various industries.

The reduction of carbon emissions from the production of green hydrogen contributes to cleaner air quality and helps combat climate change. As industries seek to decarbonize and transition to sustainable energy sources, green hydrogen provides a crucial solution for meeting these environmental goals.

Green hydrogen has diverse applications across various industries, contributing to the decarbonization of sectors that are challenging to electrify directly.

Transportation:

One of the key applications of green hydrogen is in the transportation sector. Hydrogen fuel cells can power electric vehicles, providing a clean and efficient alternative to traditional internal combustion engines. This is particularly relevant for heavy-duty vehicles, such as trucks, buses, and trains, where the energy density and quick refueling capabilities of hydrogen offer advantages over battery-electric vehicles.

Industry:

Green hydrogen serves as a valuable feedstock in industrial processes. Industries such as chemicals, refineries, and steel production can integrate green hydrogen into their operations, reducing reliance on fossil fuels and lowering overall carbon emissions. The versatility of hydrogen makes it a promising candidate for replacing traditional hydrocarbon-based feedstocks in various industrial applications.

Energy Storage:

Hydrogen can be utilized as a means of energy storage, addressing the intermittent nature of renewable energy sources like solar and wind. Excess energy generated during periods of high renewable energy production can be used for electrolysis, producing hydrogen. This hydrogen can then be stored and later converted back to electricity through fuel cells when energy demand is high or renewable energy generation is low.

Infrastructure:

The development of a robust infrastructure for green hydrogen production, distribution, and storage is another critical challenge. To facilitate the widespread adoption of green hydrogen, there is a need for investment in infrastructure such as electrolysis facilities, hydrogen storage solutions, and an extensive network of hydrogen refueling stations. The lack of a well-established infrastructure can impede the seamless integration of green hydrogen into existing energy systems.

Technological Advancements:

Continuous research and development are essential to enhance the efficiency and reduce the capital and operational costs of electrolysis technologies. Advancements in electrolyzer design, materials, and manufacturing processes are crucial for making green hydrogen economically competitive with conventional hydrogen production methods.

Market:

As of 2022, the global hydrogen market was valued at $155 billion and was expected to grow at an average (CAGR) of 9.3% between 2023 and 2030. Of this market, green hydrogen accounted for about $4.2 billion (2.7%). Due to the higher cost of production, green hydrogen represents a smaller fraction of the hydrogen produced compared to its share of market value. The majority of hydrogen produced in 2020 was derived from fossil fuel. 99% came from carbon-based sources. Electrolysis-driven production represents less than 0.1% of the total, of which only a part is powered by renewable electricity.

The current high cost of production is the main factor limiting the use of green hydrogen. A price of $2/kg is considered by many to be a potential tipping point that would make green hydrogen competitive against grey hydrogen. It is cheapest to produce green hydrogen with surplus renewable power that would otherwise be curtailed, which favours electrolysers capable of responding to low and variable power levels (such as proton exchange membrane electrolysers).

The cost of electrolysers fell by 60% from 2010 to 2022, and green hydrogen production costs are forecasted to fall significantly to 2030 and 2050, driving down the cost of green hydrogen alongside the falling cost of renewable power generation. Goldman Sachs analysis observed in 2022, just prior to Russia’s invasion of Ukraine that the “unique dynamic in Europe with historically high gas and carbon prices is already leading to green H2 cost parity with grey across key parts of the region”, and anticipated that globally green hydrogen achieve cost parity with grey hydrogen by 2030, earlier if a global carbon tax were placed on grey hydrogen.

As of 2021, the green hydrogen investment pipeline was estimated at 121 gigawatts of electrolyser capacity across 136 projects in planning and development phases, totaling over $500 billion If all projects in the pipeline were built, they could account for 10% of hydrogen production by 2030. The market could be worth over $1 trillion a year by 2050 according to Goldman Sachs. An energy market analyst suggested in early 2021 that the price of green hydrogen would drop 70% by 2031 in countries that have cheap renewable energy.

Various countries and regions worldwide have recognized the potential of green hydrogen and have initiated efforts to promote its development.

Some of the largest green hydrogen projects in the world include:

India: Reliance Industries announced its plan to use about 3 gigawatts (GW) of solar energy to generate 400,000 tonnes of hydrogen. Adani Group announced plans to invest $70 billion to become the world’s largest renewable energy company, and produce the cheapest hydrogen across the globe. The power ministry of India has stated that India intends to produce a cumulative 5 million tonnes of green hydrogen by 2030.

In April 2022, the public sector Oil India Limited (OIL), which is headquartered in eastern Assam’s Duliajan, set up India’s first 99.99% pure green hydrogen pilot plant in keeping with the goal of “making the country ready for the pilot-scale production of hydrogen and its use in various applications” while “research and development efforts are ongoing for a reduction in the cost of production, storage and the transportation” of hydrogen.

An updated report published by the World Economic Forum in June, following the plan’s announcement, Alliance launched the Renewable Hydrogen 100 initiative, which aims to boost the capacity of green hydrogen electrolyzers to 100 gigawatts by 2030, ultimately producing 7.7 MMT of hydrogen annually.